Preferred fits

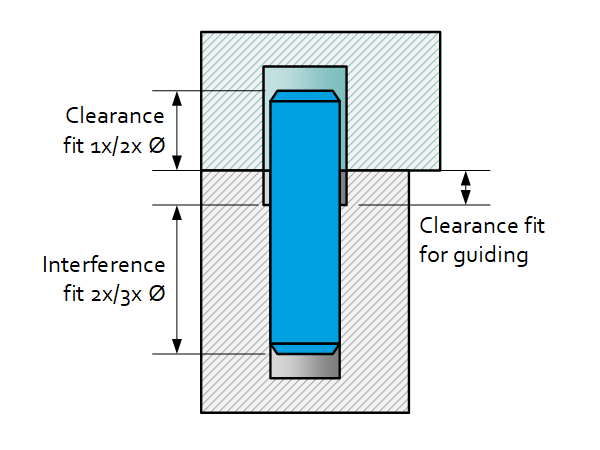

The table below shows the preferred fits according to ANSI B4.2-1978 with its overlap with the preferred fits of ISO 286-1 (2010) marked in green. Fits on shaft basis are preferred because of the availability of h6 dowel pins. For precision mechanisms G7/h6 is generally used as H7/h6 has a risk of getting stuck when parts are very clean or have surface defects. Regarding the depth of dowel pins in parts, for transition and interference fits a depth of 2x to 3x the nominal pin diameter is recommended. For a clearance fit lower depth is recommended to reduce the risk of the pin getting stuck: 1x to 2x the nominal pin diameter. For interference fits, a transition from a clearance fit to an interference fit can be used to guide the shaft into the hole, e.g. a hole that changes from G7 to P7 (in combination with a h6 shaft) to end up with a P7/h6 interference fit.

| ISO symbol* | Description | |||

|---|---|---|---|---|

| Hole basis | Shaft basis | |||

| Clearance fits | H11/c11 | C11/h11 | Loose running fit for wide commercial tolerances or allowances on external members. | More clearance |

| H9/d9 | D9/h9 D10/h6 | Free running fit not for use where accuracy is essential, but good for large temperature variations, high running speeds, or heavy journal pressures. | ||

| H8/f7 | F8/h7 F7/h6 | Close running fit for running on accurate machines and for accurate location at moderate speeds and journal pressures. | ||

| H7/g6 | G7/h6 | Sliding fit not intended to run freely, but to move and turn freely and locate accurately. | ||

| H7/h6 | H7/h6 | Locational clearance fit provides snug fit for locating stationary parts; but can be freely assembled and disassembled. | ||

| Transition fits | H7/k6 | K7/h6 | Locational transition fit for accurate location, a compromise between clearance and interference. Effective joining by means of hand-held hammer. | |

| H7/n6 | N7/h6 | Locational transition fit for more accurate location where greater interference is permissible. Joining achievable by means of press. | ||

| Interference fits | H7/p6 | P7/h6 | Locational interference fit for parts requiring rigidity and alignment with prime accuracy of location but without special bore pressure requirements. | |

| H7/s6 | S7/h6 | Medium drive fit for ordinary steel parts or shrink fits on light sections, the tightest fit usable with cast iron. | ||

| H7/u6 | U7/h6 | Force fit suitable for parts which can be highly stressed or for shrink fits where the heavy pressing forces required are impractical. | More interference | |

*Green: preferred fits according to ISO 286-1 (2010) & ANSI B4.2-1978, Black: preferred fits according to ANSI B4.2-1978, Blue: alternative fits based on h6 shafts.

Hole tolerances for preferred fits up to 400 mm

| Nominal hole sizes (mm) | Tolerance class symbol (tolerances in μm) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Above | Up to and including | C11 | D9 | D10 | F7 | F8 | G7 | H7 | H8 | H9 | H11 | K7 | N7 | P7 | S7 | U7 |

| 0 | 3 | +120 +60 | +45 +20 | +60 +20 | +16 +6 | +20 +6 | +12 +2 | +10 0 | +14 0 | +25 0 | +60 0 | 0 -10 | -4 -14 | -6 -12 | -14 -24 | -18 -28 |

| 3 | 6 | +145 +70 | +60 +30 | +78 +30 | +22 +10 | +28 +10 | +16 +4 | +12 0 | +18 0 | +30 0 | +75 0 | +3 -9 | -4 -16 | -8 -20 | -15 -27 | -19 -31 |

| 6 | 10 | +170 +80 | +76 +40 | +98 +40 | +28 +13 | +35 +13 | +20 +5 | +15 0 | +22 0 | +36 0 | +90 0 | +5 -10 | -4 -19 | -9 -24 | -17 -32 | -22 -37 |

| 10 | 18 | +205 +95 | +93 +50 | +120 +50 | +34 +16 | +43 +16 | +24 +6 | +18 0 | +27 0 | +43 0 | +110 0 | +6 -12 | -5 -23 | -11 -29 | -21 -39 | -26 -44 |

| 18 | 24 | +240 +110 | +117 +65 | +149 +65 | +41 +20 | +53 +20 | +28 +7 | +21 0 | +33 0 | +52 0 | +130 0 | +6 -15 | -7 -28 | -14 -35 | -27 -48 | -33 -54 |

| 24 | 30 | +240 +110 | +117 +65 | +149 +65 | +41 +20 | +53 +20 | +28 +7 | +21 0 | +33 0 | +52 0 | +130 0 | +6 -15 | -7 -28 | -14 -35 | -27 -48 | -40 -61 |

| 30 | 40 | +280 +120 | +142 +80 | +180 +80 | +50 +25 | +64 +25 | +34 +9 | +25 0 | +39 0 | +62 0 | +160 0 | +7 -18 | -8 -33 | -17 -42 | -34 -59 | -51 -76 |

| 40 | 50 | +290 +130 | +142 +80 | +180 +80 | +50 +25 | +64 +25 | +34 +9 | +25 0 | +39 0 | +62 0 | +160 0 | +7 -18 | -8 -33 | -17 -42 | -34 -59 | -61 -86 |

| 50 | 65 | +330 +140 | +174 +100 | +220 +100 | +60 +30 | +76 +30 | +40 +10 | +30 0 | +46 0 | +74 0 | +190 0 | +9 -21 | -9 -39 | -21 -51 | -42 -72 | -76 -106 |

| 65 | 80 | +340 +150 | +174 +100 | +220 +100 | +60 +30 | +76 +30 | +40 +10 | +30 0 | +46 0 | +74 0 | +190 0 | +9 -21 | -9 -39 | -21 -51 | -48 -78 | -91 -121 |

| 80 | 100 | +390 +170 | +207 +120 | +260 +120 | +71 +36 | +90 +36 | +47 +12 | +35 0 | +54 0 | +87 0 | +220 0 | +10 -25 | -10 -45 | -24 -59 | -58 -93 | -111 -146 |

| 100 | 120 | +400 +180 | +207 +120 | +260 +120 | +71 +36 | +90 +36 | +47 +12 | +35 0 | +54 0 | +87 0 | +220 0 | +10 -25 | -10 -45 | -24 -59 | -66 -101 | -131 -166 |

| 120 | 140 | +450 +200 | +245 +145 | +305 +145 | +83 +43 | +106 +43 | +54 +14 | +40 0 | +63 0 | +100 0 | +250 0 | +12 -28 | -12 -52 | -28 -68 | -77 -117 | -155 -195 |

| 140 | 160 | +460 +210 | +245 +145 | +305 +145 | +83 +43 | +106 +43 | +54 +14 | +40 0 | +63 0 | +100 0 | +250 0 | +12 -28 | -12 -52 | -28 -68 | -85 -125 | -175 -215 |

| 160 | 180 | +480 +230 | +245 +145 | +305 +145 | +83 +43 | +106 +43 | +54 +14 | +40 0 | +63 0 | +100 0 | +250 0 | +12 -28 | -12 -52 | -28 -68 | -93 -133 | -195 -235 |

| 180 | 200 | +530 +240 | +285 +170 | +355 +170 | +96 +50 | +122 +50 | +61 +15 | +46 0 | +72 0 | +115 0 | +290 0 | +13 -33 | -14 -60 | -33 -79 | -105 -151 | -219 -265 |

| 200 | 225 | +550 +260 | +285 +170 | +355 +170 | +96 +50 | +122 +50 | +61 +15 | +46 0 | +72 0 | +115 0 | +290 0 | +13 -33 | -14 -60 | -33 -79 | -113 -159 | -241 -287 |

| 225 | 250 | +570 +280 | +285 +170 | +355 +170 | +96 +50 | +122 +50 | +61 +15 | +46 0 | +72 0 | +115 0 | +290 0 | +13 -33 | -14 -60 | -33 -79 | -123 -169 | -267 -313 |

| 250 | 280 | +620 +300 | +320 +190 | +400 +190 | +108 +56 | +137 +56 | +69 +17 | +52 0 | +81 0 | +130 0 | +320 0 | +16 -36 | -14 -66 | -36 -88 | -138 -190 | -295 -347 |

| 280 | 315 | +650 +330 | +320 +190 | +400 +190 | +108 +56 | +137 +56 | +69 +17 | +52 0 | +81 0 | +130 0 | +320 0 | +16 -36 | -14 -66 | -36 -88 | -150 -202 | -330 -382 |

| 315 | 355 | +720 +360 | +350 +210 | +440 +210 | +119 +62 | +151 +62 | +75 +18 | +57 0 | +89 0 | +140 0 | +360 0 | +17 -40 | -16 -73 | -41 -98 | -169 -226 | -369 -426 |

| 355 | 400 | +760 +400 | +350 +210 | +440 +210 | +119 +62 | +151 +62 | +75 +18 | +57 0 | +89 0 | +140 0 | +360 0 | +17 -40 | -16 -73 | -41 -98 | -187 -244 | -414 -471 |

Shaft tolerances for preferred fits up to 400 mm

| Nominal shaft sizes (mm) | Tolerance class symbol (tolerances in μm) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Above | Up to and including | c11 | d9 | f7 | g6 | h6 | h7 | h9 | h11 | k6 | n6 | p6 | s6 | u6 |

| 0 | 3 | -60 -120 | -20 -45 | -6 -16 | -2 -8 | 0 -6 | 0 -10 | 0 -25 | 0 -60 | +6 0 | +10 +4 | +12 +6 | +20 +14 | +24 +18 |

| 3 | 6 | -70 -145 | -30 -60 | -10 -22 | -4 -12 | 0 -8 | 0 -12 | 0 -30 | 0 -75 | +9 +1 | +16 +8 | +20 +12 | +27 +19 | +31 +23 |

| 6 | 10 | -80 -170 | -40 -76 | -13 -28 | -5 -14 | 0 -9 | 0 -15 | 0 -36 | 0 -90 | +10 +1 | +19 +10 | +24 +15 | +32 +23 | +37 +28 |

| 10 | 18 | -95 -205 | -50 -93 | -16 -34 | -6 -17 | 0 -11 | 0 -18 | 0 -43 | 0 -110 | +12 +1 | +23 +12 | +29 +18 | +39 +28 | +44 +33 |

| 18 | 24 | -110 -240 | -65 -117 | -20 -41 | -7 -20 | 0 -13 | 0 -21 | 0 -52 | 0 -130 | +15 +2 | +28 +15 | +35 +22 | +48 +35 | +54 +41 |

| 24 | 30 | -110 -240 | -65 -117 | -20 -41 | -7 -20 | 0 -13 | 0 -21 | 0 -52 | 0 -130 | +15 +2 | +28 +15 | +35 +22 | +48 +35 | +61 +48 |

| 30 | 40 | -120 -280 | -80 -142 | -25 -50 | -9 -25 | 0 -16 | 0 -25 | 0 -62 | 0 -160 | +18 +2 | +33 +17 | +42 +26 | +59 +43 | +76 +60 |

| 40 | 50 | -130 -290 | -80 -142 | -25 -50 | -9 -25 | 0 -16 | 0 -25 | 0 -62 | 0 -160 | +18 +2 | +33 +17 | +42 +26 | +59 +43 | +86 +70 |

| 50 | 65 | -140 -330 | -100 -174 | -30 -60 | -10 -29 | 0 -19 | 0 -30 | 0 -74 | 0 -190 | +21 +2 | +39 +20 | +51 +32 | +72 +53 | +106 +87 |

| 65 | 80 | -150 -340 | -100 -174 | -30 -60 | -10 -29 | 0 -19 | 0 -30 | 0 -74 | 0 -190 | +21 +2 | +39 +20 | +51 +32 | +78 +59 | +121 +102 |

| 80 | 100 | -170 -390 | -120 -207 | -36 -71 | -12 -34 | 0 -22 | 0 -35 | 0 -87 | 0 -220 | +25 +3 | +45 +23 | +59 +37 | +93 +71 | +146 +124 |

| 100 | 120 | -180 -400 | -120 -207 | -36 -71 | -12 -34 | 0 -22 | 0 -35 | 0 -87 | 0 -220 | +25 +3 | +45 +23 | +59 +37 | +101 +79 | +166 +144 |

| 120 | 140 | -200 -450 | -145 -245 | -43 -83 | -14 -39 | 0 -25 | 0 -40 | 0 -100 | 0 -250 | +28 +3 | +52 +27 | +68 +43 | +117 +92 | +195 +170 |

| 140 | 160 | -210 -460 | -145 -245 | -43 -83 | -14 -39 | 0 -25 | 0 -40 | 0 -100 | 0 -250 | +28 +3 | +52 +27 | +68 +43 | +125 +100 | +215 +190 |

| 160 | 180 | -230 -480 | -145 -245 | -43 -83 | -14 -39 | 0 -25 | 0 -40 | 0 -100 | 0 -250 | +28 +3 | +52 +27 | +68 +43 | +133 +108 | +235 +210 |

| 180 | 200 | -240 -530 | -170 -285 | -50 -96 | -15 -44 | 0 -29 | 0 -46 | 0 -115 | 0 -290 | +33 +4 | +60 +31 | +79 +50 | +151 +122 | +265 +236 |

| 200 | 225 | -260 -550 | -170 -285 | -50 -96 | -15 -44 | 0 -29 | 0 -46 | 0 -115 | 0 -290 | +33 +4 | +60 +31 | +79 +50 | +159 +130 | +287 +258 |

| 225 | 250 | -280 -570 | -170 -285 | -50 -96 | -15 -44 | 0 -29 | 0 -46 | 0 -115 | 0 -290 | +33 +4 | +60 +31 | +79 +50 | +169 +140 | +313 +284 |

| 250 | 280 | -300 -620 | -190 -320 | -56 -108 | -17 -49 | 0 -32 | 0 -52 | 0 -130 | 0 -320 | +36 +4 | +66 +34 | +88 +56 | +190 +158 | +347 +315 |

| 280 | 315 | -330 -650 | -190 -320 | -56 -108 | -17 -49 | 0 -32 | 0 -52 | 0 -130 | 0 -320 | +36 +4 | +66 +34 | +88 +56 | +202 +170 | +382 +350 |

| 315 | 355 | -360 -720 | -210 -350 | -62 -119 | -18 -54 | 0 -36 | 0 -57 | 0 -140 | 0 -360 | +40 +4 | +73 +37 | +98 +62 | +226 +190 | +426 +390 |

| 355 | 400 | -400 -760 | -210 -350 | -62 -119 | -18 -54 | 0 -36 | 0 -57 | 0 -140 | 0 -360 | +40 +4 | +73 +37 | +98 +62 | +244 +208 | +471 +435 |