Home » About Us

Precision Engineering & Mechatronics: Why JPE?

We Know How to Develop Bespoke Solutions in the Field of High Tech Mechatronics Systems and Instruments

Custom Solutions

You can trust us to provide a tailored solution for your application where accurate positioning is involved. In ambient, vacuum or cryogenic environment. For static and dynamic applications.

Expert in the Field

We have over 30 years experience in designing for precision positioning applications. Our creativity is only limited by the laws of physics. Our innovation power is proven by a long list of patents.

Let's Do It!

Our approach is pragmatic. Being an independent company we can adapt to your needs and act quick and effectively. We are committed to solve your positioning challenge!

Our Mission

JPE is a leading center of expertise in precision engineering.

We develop custom systems for high precision applications in high-tech machinery and scientific instrumentation, and cryogenic positioning products for scientific research.

Our Vision

At JPE we are driven by innovation. We are inspired by working in continuously different pioneering applications.

We believe in the power of strong, personal and technical interaction in the cooperation with customers and partners. This enables a constant growth of knowledge and skills for both our customers and for JPE.

We use this progression to strengthen our position as leading center of expertise in the field of precision engineering which empowers us to keep stretching the boundaries of technology.

Our Track Record

A Long List of Patents Proves our Innovation Power

- Mask alignment in three degrees of freedom

- Optical chopper with combined tip/tilt movement

- Active vibration isolation for ambulance stretchers

- Cryogenic positioning stage

- Piezo based inertial cam drive

- Inertial drive system with friction release

- Cryogenic compatible actuator

- Cryogenic compatible slide actuator

- Play-free Optical Mount

And many more…

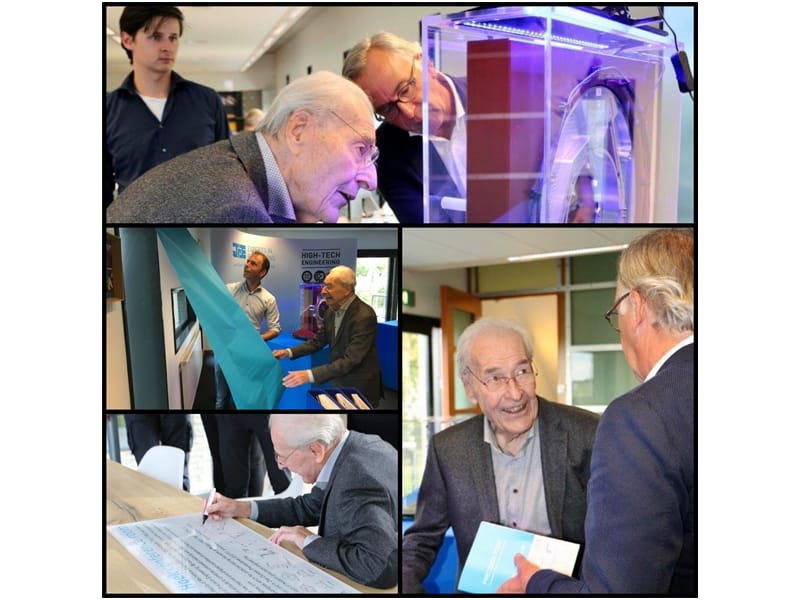

In the Spotlight

Meet our Team

Bart van Bree

System Engineer

Cryo & UHV Products

+31(0)43-3585777

Marianne Bastiaens

Management Assistant

Office

+31(0)43-3585777

Our Customers

From all around the world, our customers get the best solutions!

Our Customers

Testimonials

The contribution of JPE towards our efforts to detect dark matter axions with our MADMAX project is extremely valuable. Thanks to their expertise in high precision movement under extreme conditions such as temperature close to absolute zero and a high magnetic-field, we could eliminate one of our main potential show stoppers (2 meter stroke in cryogenic environment) on the path to making our dream of building our experiment reality.”

Dr. Béla Majorovits, from the Max Planck Institute for Physics

JPE has provided us with two valuable services. The first is their Piezoknob motor, which has greatly improved the stability, rigidity, and reliability of our cryogenic translation stages. Our experiment uses nine of these motors, and they have all worked on multiple cooldowns. The second service is JPE’s input on the mechanical design of our experiment. They improved the design of our flexure mounts and of the overall assembly of the cryogenic stage, leading to a more robust experiment. Interacting with them has been very easy and productive.

Jack Harris, Associate Professor of Physics, Yale University

Professor Harris studies the quantum aspects of motion in mechanical, optical, and electronic systems. His experiments use ultrasensitive force detectors to measure the ground state properties of electrical circuits, the quantum back-action of displacement measurements, and eventually the quantum properties of the mechanical force sensors themselves.

Thank you for sending me the Precision Point bulletin (and the website is great!). I will point my students to it!

Alexander H. Slocum, Professor of Mechanical Engineering, MIT University

MIT Professor, July 1998 Present

Research Interests: MEMS, Nanotechnology, Precision Engineering; Machine Design; Product Design; Going faster on my snowboard, staying down longer SCUBA diving!

Teaching Interests: Precision Machine Design; Design; Urban Design Corps; Physics via sports

JPE developed an extremely complex cryogenic robotic mask unit to be installed in a last generation astronomical instrument for a 10m class telescope. This system has over one hundred cryogenic linear moving parts with positioning accuracies of a few microns to be attained in an environment at around -200ºC.

The unit is now complete and fully functional. Throughout the different phases of the project, we have worked increasingly closely with the staff of JPE and can attest to their dedication and professional ability. We have been very happy with the choice of JPE as the main contractor for the project.

Dr. Francisco Garzón López, Researcher, IAC

Principal Investigator EMIR Consortium at the Instituto Astrofísica de Canarias (Tenerife, Spain)

Professor at the Astrophysics department of the University La Laguna (Tenerife, Spain)

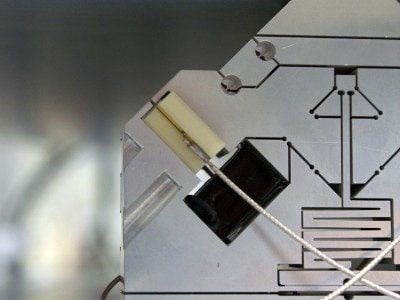

For the METIS instrument on the future 39m European Extremely Large Telescope (E-ELT), JPE has been developing a challenging optical beam chopping mirror for NOVA (Dutch university astronomy departments). Not only has the mirror to move extremely fast and accurate in all directions, but it has to operate at -200 degrees Celsius and perform more than a hundred million cycles. In order to reach its very tight performance requirements, the compact design had to accommodate interferometric sensors. JPE took care of the design, construction, testing, and documentation. Throughout the development, the interaction was pleasant, constructive and efficient, and we will certainly consider JPE for future projects.

Dr. Bernhard Brandl, Professor of Infrared Astronomy, Principle Investigator of METIS, an astronomical instrument on the E-ELT.

Bernhard’s scientific interests are:

- Starburst galaxies and HII regions

- Instrumentation for near- and mid-infrared astronomy

- New technologies for large optical telescopes

HVE develops and produces particle accelerator systems for scientific and industrial applications. Faced with a complex and relatively new project with a challenging deadline, JPE was contracted for the design of an end-station for industrial wafer implantation. The people at JPE quickly understood the specific requirements for our machines and came up with the right concept from the start. All specifications were realized, and the project was successfully completed.

Our working relationship has been pleasant and very constructive. JPE’s practical approach and technical know-how are much appreciated at HVE.

Wilfred Vroegop, Mechanical Lead Engineer at High Voltage Engineering (HVE).

Movement of a sample during a neutron scattering experiment at low temperatures and very high magnetic fields is an unusual and difficult task. High mechanical precision is needed and the measurement should not be perturbed by heat input for example during movement. The development of this tool was possible in collaboration with JPE because they were able to work very closely together with our team and understand all our requirements in detail. So we did not only profit of JPE’s products and JPE’s expertise in general, we received a specially adapted design for our very special experimental situation. The collaboration was always constructive and therefore perfectly efficient.

Dr. Peter Smeibidl, Deputy Head of Department High Field Magnet & Extreme Environment Diffractometer, Helmholtz Centre Berlin (Germany).

Our Skills

High Tech Engineering is in our DNA!

System Architecture

We treat your problem as if it is our own

- Concept design

- Feasibility study

- Specification

- System engineering

- Creative brainstorming

- Dynamic analysis

- CE directive

Analysis & Feasibility

It is in our nature to search for the essence of a problem

- Dynamics analysis

- Physics analysis

- Analytical studies

- Thermal FEM

- Static/dynamic FEM

- EMC analysis

Precision Engineering

Design for stiffness for extreme accuracies and stabilities

- High stiffness, low mass, symmetry

- Kinematic constraints

- Flexure mechanisms

- Play free / Frictionless / low hysteresis

- Statically and thermically stable

- Design for vacuum

- Design for cryogenic

Mechatronics & Control

We strive to a well-balanced mixture of mechanics, electronics and software

- High stiffness, low mass, symmetry

- Flexure mechanisms

- Servo / Feedforward systems

- Vibration control

- Actuator design

- Sensor design

- Matlab / Simulink / XPc

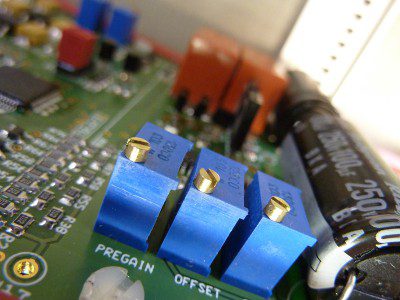

Electronics & Software

High performance of systems through dedicated electronics and software

- Analog / Digital electronics

- (soft-) logic designs

- High speed / low noise

- Power electronics

- Signal processing

- Embedded software

- User interface software

- C / C++ programming

Integration & Testing

Integration and testing in cleanroom / vacuum / cryo

- Facility: cleanroom

- Facility: closed cycle cryostat

- Facility: vacuum chamber

- In-house electronic testing equipment

- XPc 6DOF Generic Control Platform

- Labview

Vacancies

It's fun, it's different, it's challenging! See if you fit in.

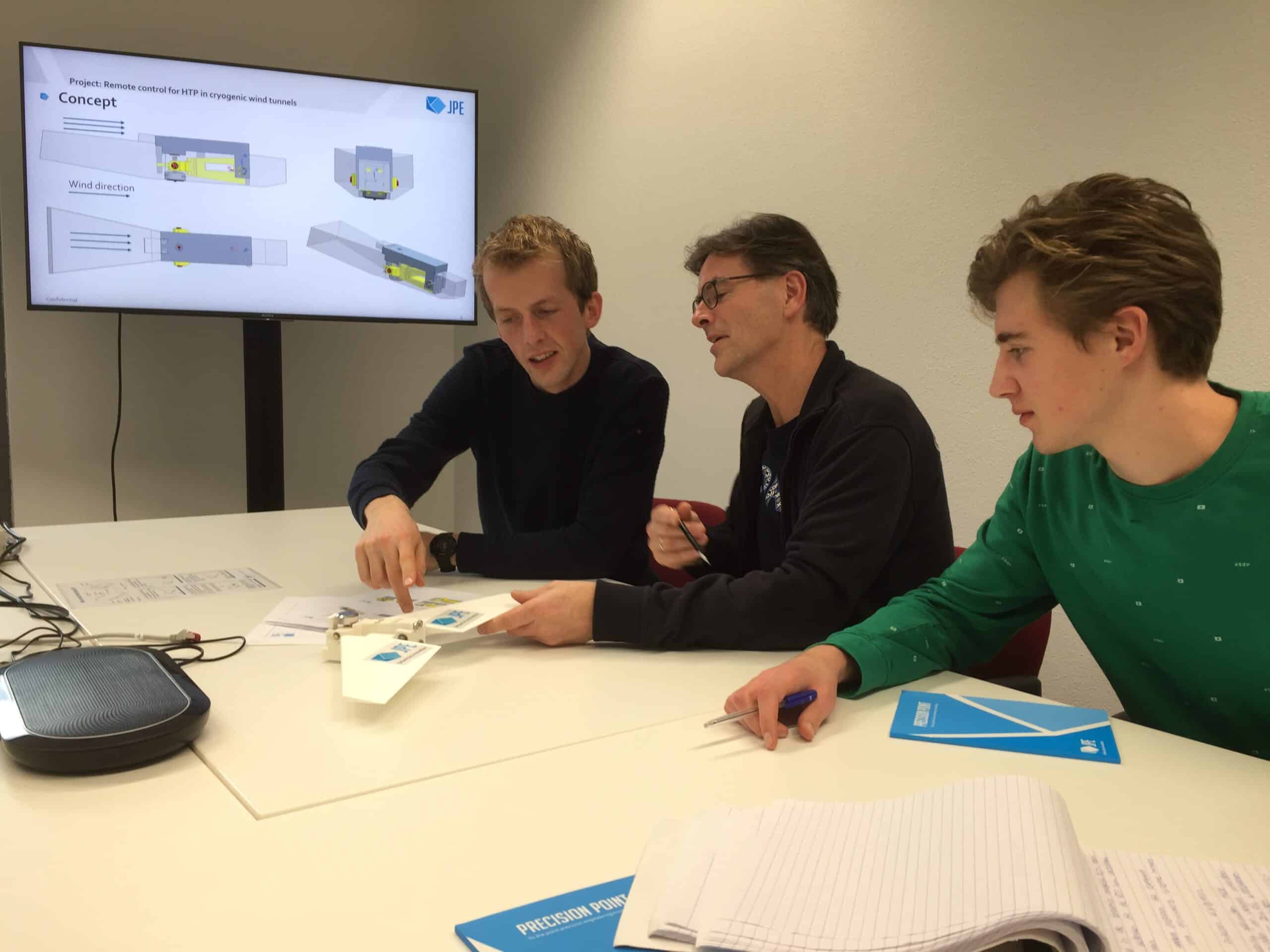

Our team has a shared passion for the development of systems for high precision applications. We work in small and dedicated project teams which requires a broad skill set to be effective, as the field of work ranges from creating architecture concepts for new systems, down to tackling integration issues when building a cutting edge, first-of-a-kind system.

The background of our team is mostly in engineering disciplines: Mechanical / Electronics / Mechatronics / Software engineering. In order to be effective within our development team, each member should have good communication skills as well as the ability to think in a multidisciplinary and creative way. We have an open and flat organization structure. So there is plenty of room to improve your personal and technical skills too.

If you think working in this high-tech environment may be something for you, take a look at our vacancies below.