Home » High Tech Engineering

Innovative Solutions Developed for Your Precision Application

JPE is a leading expert in project based development of (opto-)mechanic and mechatronic systems for high precision applications. We work for customers in high-tech industry and scientific research that want to enhance their systems or tooling with advanced solutions in mechatronics or precision engineering. Learn more about what we can do for you by choosing one of the following fields.

Our Competences

With more than 25 years of experience we master all the competences to create a solution for any high precision application. Our highly educated and multidisciplinary experts create the best solution for your application by combining our creativity, knowledge and experience.

System Architecture

We use common system engineering methods (e.g. V-model) and follow a structured design process with validated steps at all levels and stage of the development.

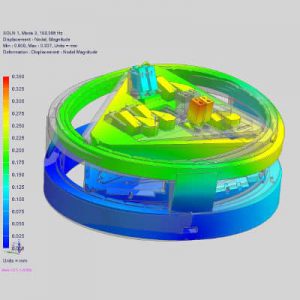

Analyses & Feasibility

We use advanced modelling techniques to perform mechanical and (thermo)dynamical optimizations and verifications of our designs.

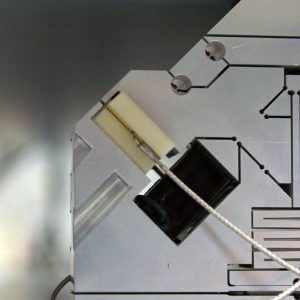

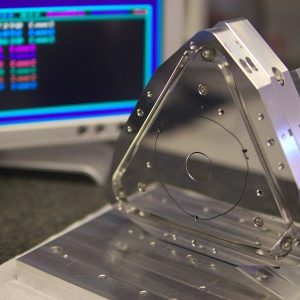

Precision Engineering

We master the ‘design principles for precision engineering’ and can easily translate these design rules into real constructions for high precision applications.

Mechatronics & Control

We use model-based design techniques to work out control strategies during the design phase. This helps to optimize the hardware design and to shorten integration time.

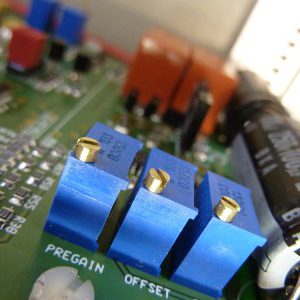

Electronics & Software

We design custom electronics to enable an integrated architecture that fits to the needs of the application. We are experienced in designing low noise analogue signal conditioning.

Support & Maintenance

Integration, testing and qualification of mechatronic systems is done in our (in-house) cleanroom by the same engineers that made the design.

Our Approach

We are an independent company which makes us flexible in every sense. We work in small and dedicated project teams with direct communication with the customer to work quick and effectively on your application. We don’t design just to meet spec’s, we are committed to solve your positioning challenge!

Request

You need an expert in precision engineering and mechatronics to develop a custom solution? Contact us!

Definition

With over 25 years of experience we quickly outline the right development strategy to find the best solution.

Concept

Our multidisciplinary engineers will find the best concept by mixing creativity, knowledge and experience.

Design

We follow a systematic approach with clear project milestones and deliver a fully documented solution.

Realization

We have a network of high class suppliers and perform assembly, integration and verification in house.

What Customers Say About Us

Our portfolio consists of diverse companies and institutes which come from many different fields and industries and are located all over the world.