Home » High Tech Engineering » High Tech Systems

Systems for High Precision Applications

Expert partner for the initial development of mechatronic systems for high precision applications. We introduce and implement the most advanced Precision Engineering solutions to improve the machines and products of high tech Original Equipment Manufacturers (OEMs).

30 Years of Experience

Leading expert in realizing complex technical systems with controlled risks

First-of-a-Kind System

Focussed on the initial development for new precision applications

From Idea to Hardware

Phased projects with clear deliverables and financial control

Leading Expert in Precision Engineering and Mechatronics

It’s our expertise that makes the difference. We are an established name in the field of precision engineering and have a long standing track record.

- We develop exclusive and innovative solutions. Our customers strengthen their IP position by our smart design contributions.

- Course leader of the training ‘Design principles for precision engineering’ at the Dutch training centre 'High-tech Institute'.

- Knowledge database: via our Precision Point platform we share our expert knowledge with engineers around the world.

- Our CEO Huub Janssen has received the ‘Rien Koster Award’ in 2010 from the Dutch Society of Precision Engineering as an acknowledgement of our innovative contributions to the field of precision engineering.

- We are ranked 8th in the '2018 Innovation top100' by the Dutch Chamber of Commerce under all SMEs over various industries in the Netherlands.

- We are part of the precision engineering community and stay up to date with the latest technological developments by active participation in the DSPE, EUSPEN and ASPE programs.

- Our involvement in 'big-science' instrumentation development enables us to transfer pioneering technological solutions from a research environment to high-tech industry applications.

What do we Offer

Working field

JPE stands for innovative mechatronic solutions for high precision applications. For more than 25 years we have been developing systems for progressive OEMs and leading high tech systems suppliers; companies that want to strengthen their market position by innovative power. Our expertise is used as a key factor to strengthen or accelerate their technological leadership.

In control of planning and budgets

The true understanding of precision engineering design principles enables us to focus on fundamental solutions. This provides a solid design baseline from the start which is crucial to be in control of the development effort and risks. On top of this we use common system engineering methods (e.g. V-model) to ensure a structured design process with validated deliverables at different levels of the system architecture and at different stages of the project.

From concept to series

Our focus lies in the development of cutting-edge systems for precision applications. It are typically one-of-a-kind systems, but it can also be first-of-a-kind systems which pave the way towards series production. That means that the realization and qualification of our solutions always are a crucial part of the project. Depending on the customer’s needs, we can involve our established network of high tech manufacturing and system integrating (sub)contractors to guarantee the continued responsibility for service and maintanance over the entire life cycle of our systems.

We are always open for new opportunities. Let’s discuss what we can do for you!

Maurice Teuwen – Engineering Operations Manager

Interested to find out what we can do for you?

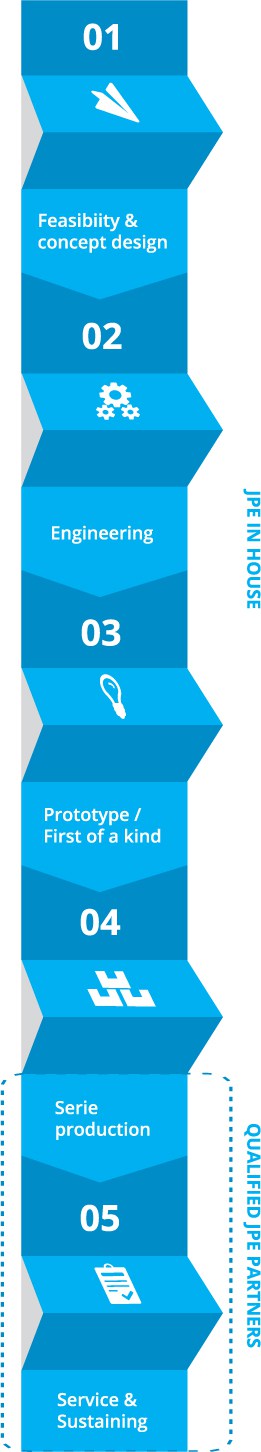

Involved in Every Step

JPE’s core competences focus on the (concept) development of new systems from idea to a qualified prototype or first-of-a-kind system.

However we can also take responsibility for series production, service and sustaining our designs by involving our established network of qualified partners. Of course it is also possible for our customers to make use of their own organization and supply chain for series production and aftercare. Due to our high quality documentation standards an efficient and effective knowledge transfer is guaranteed.

Business Cases

We respect the confidential nature of the work that we perform for our customers. Therefore we can only display a small collection of our developments. Feel free to contact us to discuss any opportunity.

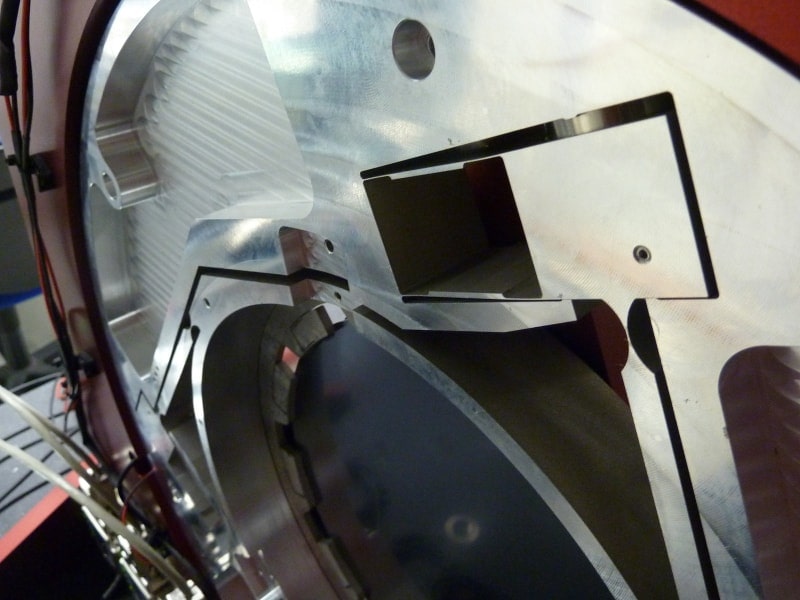

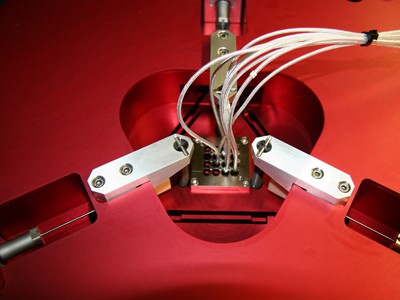

Dynamic Masking Stage

3 DOF Synchronized Motion

Problem

The customer contacted us with the desire to extend the funtionality of his optical system.

It should be made possible to dynamically move an optical masking element which always has been implemented as stationary component in the existing machine. The new solution should fit into the existing machine without any changes to the envelope and interfacing.

Solution

It was immediately clear that the required synchronized in-plane motion (3 degrees of freedom) with sub-micron accuracy was far from trivial. We choose to implement a flexure guiding design, actuated by voice coil actuators to guarantee a fully frictionless and reproducible design.

The customer followed our advice to build a demonstrator first. This created the opportunity to perform a design improvement iteration before the critical design review of the system.

Result

The introduction of the demonstrator paid off for the project. Not only to serve as a design iteration to improve a number of mechanical and electronics design features, but also to serve as a platform which was used to code and test the motion control SW.

This enabled a smooth installation of the module in the system at the customers’ site with minimal installation time. The performance was tested and completely in compliance with the agreed specifications.

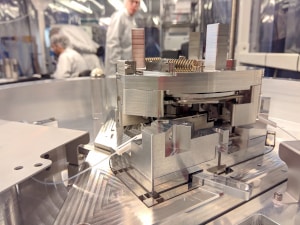

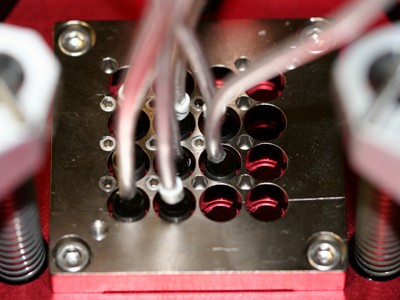

Micro-Contact Tribometer

6 DOF Force & Displacement Interaction

Problem

Within an ongoing research program the need was identified for a measurement setup to study detailed tribology behaviour within micro contact areas.

The idea was to have a system that enabled experiments in a vacuum environment, on various samples, and to measure the interactions in the tribocontacts in the sub-nanometer displacements and sub-milliNewton force ranges. Both static and dynamic.

Solution

In order to be in full control of the contact forces, it has been chosen to make a 6 DoF system. In each degree of freedom, both force and position can be measured and actuated.

Custom force cells have been developed by JPE, which have a stiffness that is balanced between force sensitivity (low stiffness) and dynamics (high stiffness). By early simulations in the design phase, the sensitivity to external vibrations has been assessed as very critical. One of the design measures that has resulted was a separate through-the-vacuumchamber-wall vibration isolation support.

Result

A very sophisticated tribology research setup has been delivered to the customer. It enables the customer to do numerous experiments under different conditions and with different sample types.

The results are used in advanced predictive simulation models that reflect on the performance of critical process steps in the customer’s machine. By having actual measurement data available from the tribo tool, the ongoing design improvements can be performed much faster and more effective providing a leading competative position for our customer.

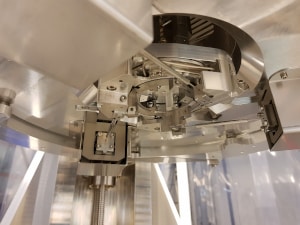

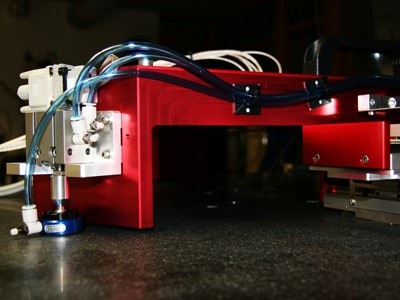

Elevation Mapping Tool

Print-Through Error of Particle Contamination

Problem

The yield of a production process that uses flat substrates was negatively affected by particles that nested in the support of the substrates. After putting all effort in reducing the numbers of particles, the customer now wanted to research possible adaptive measures to deal with the remaining level of particles without affecting the process yield. JPE was involved to develop a flexible research setup to be used in this research.

Solution

A specific test setup has been realized that creates the possibility to mimic the presence of a particle of any size underneath the substrate. This has been realized by installing a piezo element with a sharp tip, that can indent local spots of the bottom of the substrate. The effect of the indentation can be seen as an elevation of the top surface. The elevation can be measured at nanometer level by a grid of capacitive sensors. The setup can be moved easily of the total substrate area as it is hovering on airbearings.

Result

By means of the setup, the customer has executed an extensive campaign to study the mechanism of how particles affect the production process with the substrates. Based on this knowledge, additional corrective measures have been implemented in the production process. As a result, the yield of the production process has been improved further, leading to a higher profitability of the proces.