Home » High Tech Engineering » Scientific Instruments

Development of Instruments for Pioneering Research

Instrument development to enable groundbreaking scientific experiments.

Trusted and experienced partner for the scientific community.

30 Years of Scientific Experience

In working for renowned institutes in pioneering scientific research

Experienced in Contract-based Development

Experienced in contract-based development of complex instruments

Extreme Environmental Conditions

Instruments for use in vacuum, cryogenic or magnetic environments

World-class Manufacturing Technology

Embedded in the technology & manufacturing hotspot of the world

The Key to Bespoke Scientific Instruments

We stand out in the development of cutting edge, bespoke scientific instruments. We enable the scientific community to perform the most extreme experiments. These are our assets.

- We have developed instruments for the most pioneering scientific research programs. From ground based optical astronomy, to the setups used in the search for dark matter axions, to quantum computer and quantum internet experimental research.

- We are involved in front edge developments in both industry and science. This enables us to transfer innovative techniques and methods from the industry to the science instrument development. All to the benefit of our customers.

- In-house testing facilities: these facilities allow for testing in both cryogenic and vacuum environments. This enables us to validate critical design aspects in working conditions at every stage of the development. In such a way we can make fast design iterations which translates into more robust and reliable instrument operation, and minimized risks.

- Own product range of cryogenic positioners: by the development and sales of our own product line of cryogenic positioners, we have built a wealth of experience in the challenges that come with mechanisms in vacuum and cryogenic environment. Of course we use this experience in the development of bespoke modules or instruments for our customers.

What do we Offer

Precision engineering for science

We share the curiosity with respect to the questions in present fundamental science research. We deploy our expert knowledge in precision engineering and mechatronics instrument development to contribute to the advances in this field.

Contract based development

Pioneering scientific research pushes the limits of technical feasibility in instrumentation development. Therefor the development of bespoke instruments is not always easy to manage in terms of timing and budgets. On top of that, these programs are mostly executed under rigid administrative and financial regulations. This can complicate the involvement of commercial development partners. However, our leading engineering expertise and our long-term experience in this working field make that we can excel within this challenging environment.

Advanced production facilities

We have cleanroom facilities for assembly, integration and testing. We don’t have manufacturing facilities as we closely cooperate within an established network of subcontractors that is specialized in manufacturing high precision parts, optics, surface treatments, etc. These companies are part of the global technology and manufacturing hotspot, related to the vast high-tech OEM industry in our (Eindhoven) region. In such a way we can keep full focus on our key expertise which is developing innovative and pioneering scientific instrumentation.

We are always open for new opportunities. Let’s discuss what we can do for you!

Huub Janssen – CEO & founder of JPE

Interested to find out what we can do for you?

Business Cases

We respect the confidential nature of the work that we perform for our customers. Therefore we can only display a small collection of our developments. Feel free to contact us to discuss any opportunity.

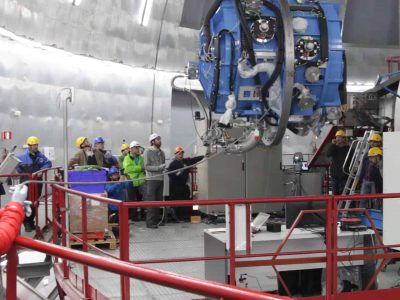

Configurable Slit Unit

Multi-Object Masking Mechanism for Astronomy

Problem

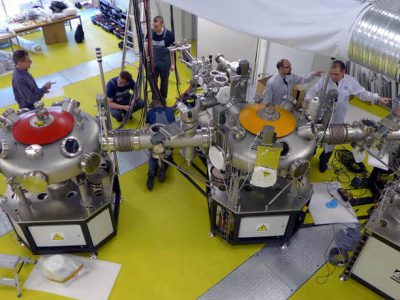

The light spectrum of stars contains valuable information for astronomy research. In order to derive the spectrum of a single, specific object in the sky it should be isolated from other objects. For the GTC telescope, the largest telescope in the world, it was envisioned to develop a configurable slit unit (CSU) for this purpose. This CSU should be able to make 55 individual slits, by inserting 110 independently driven masking bars with micrometer motion accuracy, from opposite sides of a 340 mm square field of view. And by the way, in a vacuum and 77 Kelvin (LN2) environment.

Solution

Within the given constraints of vacuum and cryogenic operation, and moreover the limited design envelope, there were no position actuators and sensors available on the market that could be used to drive the 110 individual masking elements. We came up with a promising concepts for both vital functions. Feasibility was proven by breadboard testing. From there a controlled project with integrated risk mitigation actions was defined; a clear path was followed from breadboard to a fully engineered and qualified solution via intermediate prototype milestones.

Result

The CSU is installed as part of the EMIR instrument on the Gran Telescopio Canarias on the island La Palma (Canary Islands). It is the first instrument ever which enables (re)configuration of the masking elements at cryo temperatures in astronomy. By this, the CSU enables to capture a unprecedented amount of individual objects in the sky per observation night; the observing capacity is unrivelled by factors compared to other existing observatories. This means a massive step forward for the astronomy community in the quest to build a better understanding of the universe.

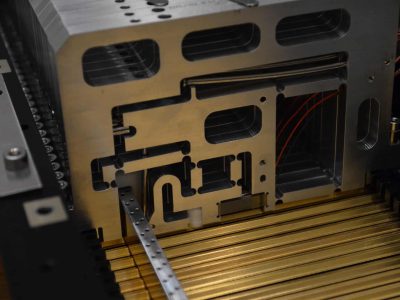

High Transmission X-Ray Spectrometer

Advanced Material Research

Problem

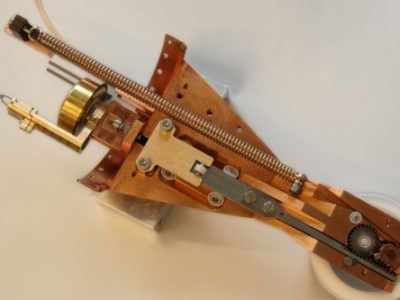

An renown cyclotron facility had identified the need to extend their capabilities for advanced material research in the direction of batteries and solar cells. More specifically, the need was identified to include a soft x-ray spectrometer within the energy range between 54.3 eV to 1836 eV. Such a system is not commercially available, though based on previous studies an optical scheme had been established for this spectrometer. Within the optical concept, a number of optical elements should be moved (gratings, aptertures, mirrors) over centimeters range with micrometer accuracy and submicron stability.

Solution

The design and realization of the spectrometer was tendered to the industry. The major challenge within the contract was not only the fullfillment of the motions, but also the stress-free and stable integration of the sensitive optical elements into the mechanism.

Out of the competition, we were contracted based on two decisive assets. The ability to use our own of-the-shelf actuators which were completely suited for the job was a decisive risk mitigation for the customer. Our long-standing expertise in kinematic and stress-free optical mounts was seen as a second crucial expertise.

Result

The spectrometer has been designed and built by JPE. Manafucturing was sub-contracted within our established network of manufacturing partners.

The spectrograph is installed at the beamline endstation and succesfully commisioned. It will enable the scientific community to further extend material research to the benefit of the whole society.

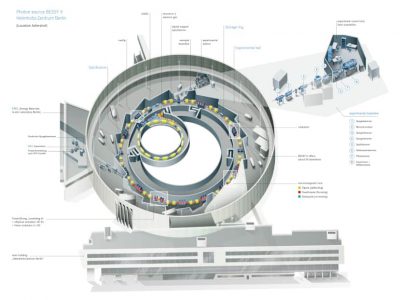

High Magnet Field Sample Rotator

Material Research by Neutron Scattering in High Magnetic Field

Problem

For various kinds of fundamental physics research, samples are placed in an extremely high magnetic field and then bombarded with neutrons. The scattering pattern of particles that are ‘blown away’ reveals valuable scientific insights.

The facility with the worldwide strongest continuous magnet for neutron scattering experiments was in need for a mechanism to rotate samples during experiments. In other words: we need a sample rotator that operates in a 25T strong magnet field, at Ultra High Vacuum pressure, and 0.5 K absolute temperature and within a very confined envelope at the extremely compact center of the magnet.

Solution

Based on our own of-the-shelf actuators with proven ability to work under these conditions, and our long-term experience in developing scientific experimental instrumentation we were selected as a partner for this development.

Due to the confined envelope availble within the magnet structure, we proposed the option to design the sample rotator mechanism as an integral part of the magnet inner core structure. This urged for a very close cooperation with the customer for proper alignment of all details, but it enabled us to come up with a bespoke design for the mechanism that fullfilled every aspect of the requirements.

Result

The sample rotator was designed and produced by JPE. The core of the mecahism was was tested at JPE facilities at 4K before transfer to the customer’s facility to ensure up-to-spec operation before installation. Thereafter, the rotator mechanism is integrated in the setup at the customer’s site. Here it will open up new possibilities for users of the High Magnetic Field Facility for Neutron Scattering and allow to do exciting new research.