Introduction

This sheet will give some basics about a vacuum chamber itself and about mechanical setups that are placed in it.

| Classification | Level [mbar] | Pumps | Sensors | Examples | |

|---|---|---|---|---|---|

| LV | Low | 103 … 100 | Dry/wet | Mechanical | Food seals, domestic vacuum cleaner |

| MV | Medium | 100 … 10-3 | Dry/wet | Mechanical | Light bulb |

| HV | High | 10-3 … 10-6 | +Turbo | Electronic | Thermos bottle insulation |

| VHV | Very high | 10-6 … 10-9 | +Turbo | Electronic | Vacuum vessel LHC CERN (particle accelerator) |

| UHV | Ultra high | 10-9 … 10-12 | +Turbo | Electronic | Atomic physics research (e.g. gravity wave) |

| EHV | Extreme high | < 10-12 | (Space) | Electronic | Space |

Pressure conversion

$1MPa\ =1\frac{N}{mm^2}=145psi=10bar $

$1mbar={10}^{-4}MPa=0.0145psi=100\frac{N}{m^2}$

Gas law

$pV=nRT$ with $R=8.314JK^{-1}mol^{-1}$

Estimates for wall thickness ($p=1$ bar)

$\tau_{0.2}\approx0.4\cdot\sigma_{0.2}$ (JPE Estimate for metals), $t=$ thickness,

$\delta=$ deformation

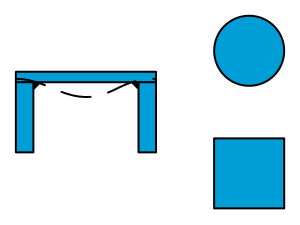

| Welded flanges | ||

| $$t=\sqrt{\frac{{3d}^2p}{2\sigma_{max}}}$$ | $$\delta=\frac{d^4p}{32{\rm Et}^3}$$ |

| $$t=\sqrt{\frac{{3pL}^2}{\sigma_{max}}}$$ | $$\delta=\frac{{\rm pL}^4}{16{\rm Et}^3}$$ | |

| O-ring-sealed flanges | ||

| $$t=\frac{dp}{2\tau_{max}}$$ | $$\delta=\frac{d^4p}{8{\rm Et}^3}$$ |

| $$t=\frac{pL}{\tau_{max}}$$ | $$\delta=\frac{{\rm pL}^4}{4{\rm Et}^3}$$ | |

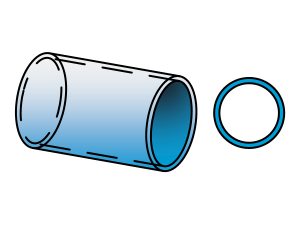

| Thin walled tubes ($r>20t$) | ||

| $$t=\frac{pr}{2\sigma_{max}}$$ | $$\delta=\frac{2\pi{\rm pr}^2}{Et}$$ |

Types of leakage

- Real leakage (holes, porous materials)

- Virtual leakage (pocket sealed with bolt)

- Desorption / outgassing (solvents)

- Diffusion (e.g. H-atoms from steel)

- Permeability (O-rings)

- Evaporation (finger prints, lubricants)

- Backflow pump (dry > wet > turbo)

Paschen’s law

This law states that the breakdown potential (necessary to start a discharge between 2 electrodes) is pressure dependent. JPE Rule: vacuum must be below ${10}^{-1}mbar$

In-vacuum-design rules of thumb

- Prevent virtual leakage: drill holes in bolts etc.

- Do not use lubricants

- Check outgassing spec’s from synthetic materials

- Be aware of high friction (dry environment)

- Use hybrid bearings

- Heat must be conducted through material (no convection)

Pumps (mbar)

- Dry: Diaphragm ${(10}^0)$, Screw $({10}^{-2})$

- Wet: Roots ${(10}^{-2})$, Rotary vane $({10}^{-4})$

- +Turbo: Molecular pump $({10}^{-10})$

- Ionization $({10}^{-11})$

Sensors (mbar)

- Mechanical:

- Bourdon ${(10}^1)$

- Diaphragm ${(10}^0)$

- Electronic:

- Piezo based ${(10}^0)$

- Capacitive ${(10}^{-3})$

- Thermal conductivity (Pirani) ${(10}^{-4})$

- Ionization

- cold: Penning ${(10}^{-8})$

- hot: Inverted magnetron ${(10}^{-12})$