Introduction

The PiezoKnob is a stepping actuator with nanometer level resolution which, when powered down, combines a high holding force with sub-nanometer stability. This is of particular interest for high precision equipment operated in vacuum and cryogenic environments where heat cannot be removed by convection and cooling power is typically limited. The inertia & stick-slip based actuation applies elementary physics as explained in this sheet.

Actuation concept

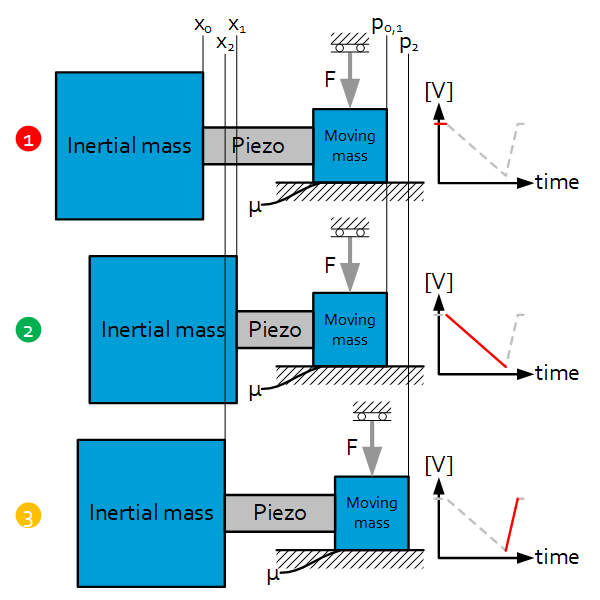

The inertial drive concept is depicted in the figure below.

Step 1

The objective is to reposition the moving mass from $p_0$ to $p_2$. In the initial condition a steady-state voltage is applied to the piezo and a normal force $F$ is applied to the moving mass to generate friction.

Step 2

Slowly decreasing the voltage shortens the piezo and the inertial mass is ‘pulled’ to position $x_1$. The moving mass remains on its initial position ($p_1 = p_0$) due to the friction.

Step 3

Now, the voltage is rapidly increased to expand the Piezo to its original length. This rapid expansion accelerates the inertial mass and the resulting force on the moving mass overcomes the friction, causing a shift to position $p_2$. Because the inertial mass is larger (more inertia) it will move less backwards than the moving mass shifts forward. After this step the system is in steady state again, at position $p_2$, ready for the next step.

PiezoKnob* design and realization

The picture shows the PiezoKnob, a linear actuator based on a rotational inertia & stick-slip drive. Inside the actuator, the linear movement of the piezo is converted into a rotation of the spindle, the moving mass, and the outer ring, the inertial mass. The contact between the spindle and its nut provides the necessary friction and because the spindle is self-locking the actuator has a high load capacity even when powered down. Furthermore, the slow drift typical for piezo elements only affects position of the outer ring and not of the spindle thus providing sub-nanometer stability to the payload.

Advantages and limitations

- Both masses can be used as a positioner

- High drive force (not limited to friction)

- When positioning using the moving mass, the low frequency piezo-drift will not influence the position

- Step size is small: in the order of 1/1000 * Piezo length which gives a high resolution

- Steps size, and thus velocity, is limited by the inertia ratio

- Variations in friction lead to variation of the step size. This can be reduced with a well-designed actuation profile.

PiezoKnob* specifications / features

- Cryogenic compatible: operational down to 1 Kelvin

- Vacuum compatible

- Nanometer position resolution

- High load capacity (up to 50 N)

- Antimagnetic materials

- Sub-nm stability

*The PiezoKnob is a JPE product, see